Air Compressors

Experience the Pure Power of BendPak USA Made Air Compressors

BendPak air compressors are now made in the USA and have a well-earned reputation for high performance and dependability. When you're concentrating on a project, you shouldn't have to worry about the temperature or moisture inside your air compressor; you just need a unit that works as hard as you do.

BendPak air compressors are now made in the USA and have a well-earned reputation for high performance and dependability. When you're concentrating on a project, you shouldn't have to worry about the temperature or moisture inside your air compressor; you just need a unit that works as hard as you do.

Our highly efficient Patriot line of air compressors are perfect air-pumping powerhouses that feature rugged cast-iron construction, high-quality Manchester Tanks, true copper piping for cooler operation, pressure control and extra-large pumps. We offer a variety of motor options for our Patriot air compressors, such as one or three phase, 50 or 60 Hz, and 5 horsepower, 7.5 horsepower, or 10 horsepower. All vertical models come standard with rugged 1/2-inch anti-vibration pads to keep the unit still during operation.

BendPak Patriot Series air compressors directly resist temperature and moisture concerns with larger pistons that operate at lower speeds. Fewer rotations per minute directly results in lower operating temperatures, but thanks to the larger piston size, you don't have to sacrifice performance. With lower a temperature comes much less moisture, ensuring your Patriot Series air compressor has a long and happy existence in your shop or garage. Whatever your high-pressure air requirements, BendPak has exactly what you need.

Is a Rotary Screw Air Compressor Worth the Cost?

There are many things to consider before you decide a rotary screw air compressor is worth a higher price. Such compressors are much quieter than traditional reciprocating (piston-type) compressors, but they're also more expensive. Then again, they tend to require less maintenance over time and can operate continuously, which makes them ideal for busy shops. This guide will walk you through your options, so you have what you need to get the BendPak air compressor with enough horsepower and CFM for your budget.

TSP-580V-601 (5179111)

Orientation: Vertical

Tank Size: 80 gallon

Horsepower: 5 HP

The TSP-5 Patriot Series air compressor features an 80-Gallon vertical tank and 5 HP, low-RPM motor for high efficiency. Built for high productivity and lower operating costs, it produces more compressed air using an extremely efficient and low-energy-consuming components. Made in USA.

VMP-7580V-601 (5179112)

Orientation: Vertical

Tank Size: 80 gallon

Horsepower: 7.5 HP

The V-Max Patriot 7580V-601 air compressor combines leading-edge technology with the superior build quality you've come to expect from the world leader in automotive service equipment. Featuring an 80-Gallon vertical tank and 7.5 HP low-RMP motor, you're ready for all your compressed air needs. Made in USA.

VMP-7580V-603 (5179113)

Orientation: Vertical

Tank Size: 80 gallon

Horsepower: 7.5 HP

Up your air game with the powerful, 3-phase V-Max Patriot 7580V-603 air compressor from BendPak. V-Max Patriot air compressors meet and exceed your air system needs with high-efficiency technology and unrivaled quality. Made in USA.

VMX-10120V-603 (5179108)

Orientation: Vertical

Tank Size: 120 gallon

Horsepower: 10 HP

Meet the enormous BendPak V-Max Elite™ 10120V-603 3-phase air compressor system. When it comes to pure air power and reliability, there's no such thing as a more solid investment.

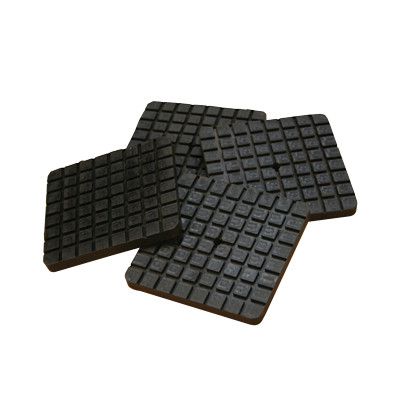

Anti-Vibration Pads (5179402)

Orientation:

Tank Size:

Horsepower:

Keep your compressor from vibrating itself into disrepair with these optional 13 mm rubber pads.

BendPak USA

BendPak USA BendPak Australia

BendPak Australia BendPak Canada

BendPak Canada BendPak Mexico

BendPak Mexico BendPak South Africa

BendPak South Africa BendPak UAE

BendPak UAE

Catalogs

Catalogs